The 4L60E Transmission Rebuild Manual is a comprehensive guide offering step-by-step instructions for rebuilding the 4L60E transmission, an essential resource for technicians and enthusiasts alike․

1․1 Overview of the 4L60E Transmission

The 4L60E is a four-speed automatic transmission produced by General Motors, known for its electronic control and versatility․ Widely used in GM vehicles, it is renowned for its durability and smooth operation․ Featuring a lock-up torque converter and overdrive, it enhances fuel efficiency and performance․ Commonly found in trucks, SUVs, and performance cars, the 4L60E is a popular choice for both stock and modified applications․ Understanding its design and functionality is crucial for a successful rebuild, as detailed in the 4L60E transmission rebuild manual․

1․2 Importance of Using a Rebuild Manual

A rebuild manual is essential for accurately overhauling the 4L60E transmission․ It provides detailed step-by-step instructions, ensuring each component is disassembled, inspected, and reassembled correctly․ The manual includes specific torque specifications, fluid recommendations, and troubleshooting tips․ Without it, critical errors may occur, leading to premature wear or transmission failure․ Technicians and enthusiasts rely on this guide to guarantee a successful rebuild, maintaining the transmission’s performance and longevity․ It serves as an invaluable resource for both novice and experienced rebuilders․

Tools and Materials Needed for the Rebuild

The 4L60E rebuild requires specialized tools like bearing pullers, presses, and socket sets․ Essential materials include new gaskets, seals, bearings, and transmission fluid․ These ensure a successful overhaul․

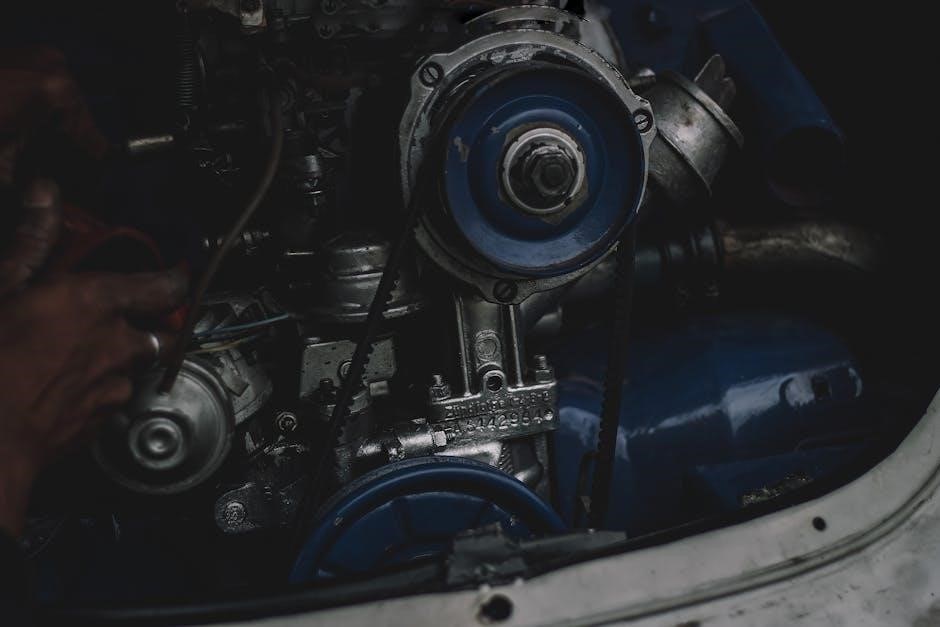

2․1 Essential Tools for Disassembly and Reassembly

The 4L60E rebuild requires specific tools for disassembly and reassembly, such as a bearing puller, transmission pan gasket scraper, and a torque wrench․ A socket set, including metric and SAE sizes, is crucial for removing bolts and fasteners․ Additionally, a hydraulic press is necessary for installing bearings and other press-fit components․ Specialty tools, like a transmission fluid pressure manual valve position switch, may also be needed․ These tools ensure precise and efficient disassembly and reassembly of key components․

2․2 Required Materials and Parts for Overhaul

For a successful 4L60E transmission overhaul, several key materials and parts are essential․ These include new gaskets, seals, and bearings to prevent leaks and wear․ A complete rebuild kit is recommended, featuring components like the torque converter, valve body, and clutch packs․ High-quality transmission fluid is also necessary for proper lubrication․ Additionally, replacement parts such as the manual valve position switch and pressure regulator valve may be required to ensure optimal performance and longevity of the transmission․

Step-by-Step Disassembly Process

The 4L60E disassembly begins with draining transmission fluid and removing the torque converter․ Next, the valve body is detached, followed by the main components like the pump and planetary gearset․

3․1 Removing the Transmission from the Vehicle

Raising the vehicle on a lift or jack stands provides access to the 4L60E transmission․ Disconnect the driveshaft, cooler lines, and electrical connectors․ Use a transmission jack to support the unit during removal․ Ensure all mounting bolts are loosened before sliding the transmission out carefully․ Proper safety equipment and a second person can assist in stabilizing the component during this process․

Once free, lower the transmission to the ground or onto a workbench for disassembly․ Always refer to the manual for specific bolt locations and torque specifications to avoid damage․

3․2 Disassembling Key Components (Torque Converter, Valve Body, etc․)

Begin by removing the torque converter, ensuring it is securely fastened to prevent damage․ Next, detach the valve body by removing the mounting bolts, taking care not to damage electrical connectors․ Use specialized tools like a puller for the torque converter and snap ring pliers for internal components․ Follow the manual’s instructions for proper disassembly sequence to avoid misalignment or damage to critical parts․ Document each step for easier reassembly later․

Inspection and Cleaning of Transmission Parts

Inspect all components for wear, damage, or contamination․ Clean parts using solvents or ultrasonic cleaners to ensure proper function․ Replace any damaged or worn items immediately․

4․1 Identifying Worn or Damaged Components

Inspect each part thoroughly for signs of wear or damage․ Common issues include scored bearings, worn gear teeth, and damaged seals․ Check the torque converter for cracks or excessive play․ Look for frayed or broken bands and warped or scored clutch packs․ Use a rebuild manual to identify acceptable wear limits․ Replace any component that shows excessive wear or damage to ensure proper transmission function and longevity․ This step is critical for a successful rebuild․

4․2 Cleaning Procedures for Reusable Parts

Clean all reusable parts thoroughly using a solvent to remove dirt, grease, and old fluid․ Use a soft-bristle brush to scrub away stubborn deposits․ Rinse parts with clean solvent and dry them completely with compressed air․ Avoid using abrasive materials that could damage surfaces․ Pay special attention to the valve body, oil pan, and other critical components; Proper cleaning ensures optimal performance and prevents contamination during reassembly․ Always follow safety guidelines when handling solvents and cleaning tools․ This step is vital for a successful rebuild․

Rebuilding and Replacing Parts

Install new gaskets, seals, and bearings, ensuring proper alignment and fitment․ Replace worn components with OEM or high-quality aftermarket parts․ Apply the correct torque specifications during reassembly․

5․1 Installing New Gaskets, Seals, and Bearings

Begin by ensuring all surfaces are clean and free of debris․ Install new gaskets and seals, aligning them precisely with mating surfaces․ Bearings should be pressed in using specialized tools, ensuring proper fitment․ Apply a thin layer of lubricant to moving parts․ Tighten all fasteners using a torque wrench, adhering to the manufacturer’s specifications․ This step is critical to prevent leaks and ensure smooth operation․ Always use high-quality, OEM-recommended parts for reliability․

5․2 Reassembling the Valve Body and Other Subcomponents

Reassembly begins with cleaning and lubricating the valve body and its components․ Install the valve pack, ensuring proper alignment with the valve body․ Reattach the throttle valve and manual valve, securing them with the correct torque specifications․ Replace any worn-out springs and pistons, ensuring they are seated properly․ Finally, reinstall the valve body into the transmission case, aligning the mounting points accurately․ Use a torque wrench to secure the bolts evenly․ Proper alignment and tightening are critical to prevent leaks and ensure smooth shifting․

Reassembly of the Transmission

Reassembly involves aligning major components, reinstalling the torque converter, and securing it properly․ Reattach the transmission pan, ensuring a leak-proof seal․ Follow the manual’s torque specifications and guidelines for a precise rebuild․

6․1 Aligning and Reinstalling Major Components

Reinstalling major components requires precise alignment to ensure proper function․ Start by aligning the torque converter with the transmission input shaft, ensuring it seats fully․ Next, reinstall the valve body, making sure it is securely fastened with the correct torque specifications․ Reattach the oil pan, ensuring a leak-proof seal by applying a new gasket․ Finally, align and reinstall the transmission case, verifying all components are properly seated and secured․ This step is critical for maintaining transmission integrity and performance․

6․2 Torque Specifications for Key Fasteners

Proper torque specifications are crucial for ensuring the transmission’s reliability․ Tighten the oil pan bolts to 10-15 ft-lbs, working in a star pattern․ The valve body bolts should be torqued to 25-30 ft-lbs, while the transmission case bolts require 35-40 ft-lbs․ Ensure all fasteners meet factory specifications to avoid damage or leaks․ Refer to the 4L60E rebuild manual for precise torque values, as over-tightening can strip threads or warp components․ Always use a torque wrench for accuracy during reassembly․

Testing and Refilling Transmission Fluid

After reassembly, bleed the transmission system to remove air bubbles․ Check fluid levels using the dipstick, ensuring it reaches the recommended mark․ Use the specified ATF type for optimal performance․ Refer to the 4L60E rebuild manual for precise bleeding procedures and fluid capacity guidelines to ensure proper transmission function and longevity․

7․1 Bleeding the Transmission System

Bleeding the transmission system is crucial to ensure proper fluid flow and pressure․ Start by raising the vehicle and locating the transmission fluid reservoir․ Use a fluid pump to prime the system, ensuring no air bubbles remain․ Cycle through the gears slowly, allowing the fluid to circulate fully․ Check for any leaks or unusual noises․ Refer to the 4L60E rebuild manual for specific bleeding procedures and safety precautions to guarantee optimal transmission performance and longevity․

7․2 Proper Fluid Level and Type Recommendations

After bleeding, ensure the transmission fluid level is accurate․ Use a high-quality Dexron VI fluid, as specified in the 4L60E rebuild manual․ Check the level with the vehicle on a level surface, engine warm, and in park․ Overfilling can damage seals, while underfilling may lead to improper lubrication․ Always verify fluid type compatibility to prevent damage․ Consult the manual for precise level checks and fluid capacity to maintain optimal transmission performance and longevity․

Common Issues and Troubleshooting

Post-rebuild issues may include leaks, slipping, or noisy operation․ Consult the 4L60E rebuild manual for troubleshooting steps to diagnose and resolve these common problems effectively․

8․1 Diagnosing Post-Rebuild Problems

After rebuilding, common issues like slipping, harsh shifts, or leaks may arise․ The 4L60E rebuild manual provides detailed troubleshooting steps, such as checking the transmission fluid pressure manual valve position switch and ensuring proper torque converter engagement․ Technical service bulletins and diagnostic procedures outlined in the guide help identify worn or misaligned components․ Systematic inspection of the valve body, clutch packs, and seals is crucial for resolving post-rebuild malfunctions effectively․

8․2 Addressing Leaks, Slipping, or Noisy Operation

Leaks, slipping, or noisy operation after a rebuild can indicate issues like faulty gaskets, worn clutch packs, or incorrect fluid levels․ The 4L60E rebuild manual suggests inspecting the valve body and torque converter for proper alignment․ Noisy operation may stem from bearing failure or improper gear engagement․ Addressing these problems involves replacing damaged components, adjusting fluid pressure, and ensuring all seals are properly seated․ Regular inspection and adherence to the manual’s guidelines can prevent recurrence of these issues․

Final Inspection and Test Drive

A thorough pre-drive inspection ensures all components are secure and functioning properly․ A test drive evaluates transmission performance, verifying smooth shifting and operation under various conditions․

9․1 Pre-Drive Checklist

A pre-drive inspection involves checking fluid levels, ensuring all connections are secure, and verifying proper installation of components․ It’s crucial to review torque specifications and ensure no leaks are present․ This step prevents potential issues during the test drive, ensuring safety and optimal performance․ Always refer to the 4L60E rebuild manual for specific guidelines to avoid overlooked details․ A thorough checklist helps in identifying any oversight before real-world testing begins․

9․2 Evaluating Transmission Performance During Test Drive

During the test drive, monitor the transmission for smooth shifting, absence of slipping, and unusual noises․ Ensure proper engagement in all gears and check for any delay in acceleration․ Verify that the torque converter locks up correctly and that there are no signs of leakage․ Avoid aggressive driving initially and gradually test under various conditions․ This evaluation ensures the rebuild was successful and identifies any remaining issues that may require adjustment or further inspection․ A satisfactory test drive confirms the transmission’s proper function and reliability․

The 4L60E Transmission Rebuild Manual provides detailed guidance for a successful overhaul․ Regular fluid checks, filter replacements, and proper driving habits ensure the transmission’s longevity and optimal performance․

10․1 Long-Term Care for the Rebuilt Transmission

Proper long-term care for the rebuilt 4L60E includes regular fluid changes using the recommended type, monitoring temperature levels, and avoiding extreme driving conditions․ Ensuring the cooling system functions correctly prevents overheating, which can damage internal components․ Additionally, prompt diagnosis of any unusual noises or performance issues helps prevent minor problems from escalating․ Following the rebuild manual guidelines ensures the transmission operates efficiently for years, maintaining its reliability and performance․

10․2 Importance of Regular Maintenance

Regular maintenance is crucial for the longevity and optimal performance of the 4L60E transmission․ This includes fluid checks, filter replacements, and inspecting for leaks․ Adhering to the rebuild manual recommendations ensures all components remain in good condition․ Neglecting routine maintenance can lead to premature wear, decreased fuel efficiency, and potential system failure․ Consistent upkeep not only preserves the transmission’s health but also enhances overall vehicle reliability and driving experience, making it a cost-effective investment in the long run․